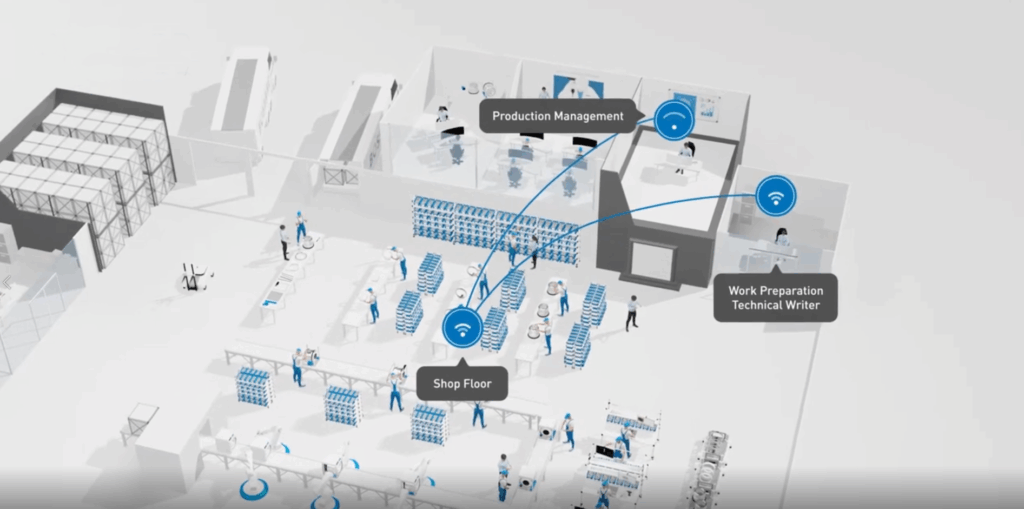

We provide comprehensive technological solutions to manage and operate factories and production lines, aiming to maximize efficiency, reduce waste, and achieve the highest levels of productivity.

Factory & Production Systems

Trusted partnerships at your service

To fulfill your requirements, we collaborate with trusted suppliers—relationships built on unwavering confidence—to seamlessly provide everything you need at every stage of your project

Customized solutions for your projects

We meet all your industrial sector needs – no matter how unique – with customized software solutions tailored to your operational goals and specific industry requirements

Deep expertise that supports you

e provide you with extensive industry expertise and sharp strategic insights, designed to ensure your projects succeed in the most competitive markets.

Order Reception & Status Tracking

Processing customer orders (internal/external), registering them in the system with instant tracking numbers and real-time status display (Under Review - In Progress - Completed) to ensure fast processing

Quotation Generation & Inventory Integration

After entering the order, the price is calculated based on quantities, components, and current cost. The system is directly linked to the raw material inventory to ensure availability before approving the request. Goal: Accurate pricing and faster execution

Production Scheduling

The system schedules each task in the production line based on priority and available production capacity. Schedules are displayed intelligently to ensure work organization and reduce machine/resource congestion. Goal: Efficient and organized task flow

Monitoring execution time and quality

The system monitors time spent on each task, measures performance against set targets, and records any quality observations – ensuring continuous improvement for high-quality production with precise timing

Work Order & Release Management

Official production orders are issued for each manufacturing stage, with full traceability from start to finish. The system includes release orders authorizing finished products to exit the production line or proceed to the next phase – ensuring granular control over every production detail

Selecting the appropriate machines for each task

For each product or task, the optimal machine type is automatically selected based on the process and raw material. Operating instructions are then sent directly to the operator or machine interface – minimizing errors and ensuring peak operational precision